I just arrived home from this evening from the first week working with my new client, the Digital Trust team at T-Systems, and my mind is spinning with ideas.

Over the coming months, I am going to be working with this team to define a set of product offerings that make the most of the investment and capabilities that T-Systems has already developed in the DLT space. Naturally, a good portion of my time this first week was spent beginning to get an understanding of what the team had already accomplished. The quality of thought that this team has displayed in its solutioning impressed me in a number of ways, but what I find myself thinking about the most is the work they’ve put into a DLT use case I have not spent any time exploring until now: discrete manufacturing process control.

I have to admit that the idea of driving a manufacturing assembly line with real-time decisions made by blockchain smart contracts did not strike me as intuitively obvious. Assembly lines might manufacture goods for different clients, but typically on behalf of a single manufacturing enterprise; I failed to understand how having DLT drive assembly decisions would add value. Could you accomplish the same thing less expensively with a single, non-distributed application? Where was the potential for world-changing transformation that we see with other DLT use cases?

The way that the Digital Trust team chose to illustrate that potential was nothing short of brilliant. Being part of Deutsche Telekom affords access to a wide variety of capabilities, and in this instance the team really made the most of that: they constructed a working model assembly line which actually took instructions in real time from a blockchain smart contract.

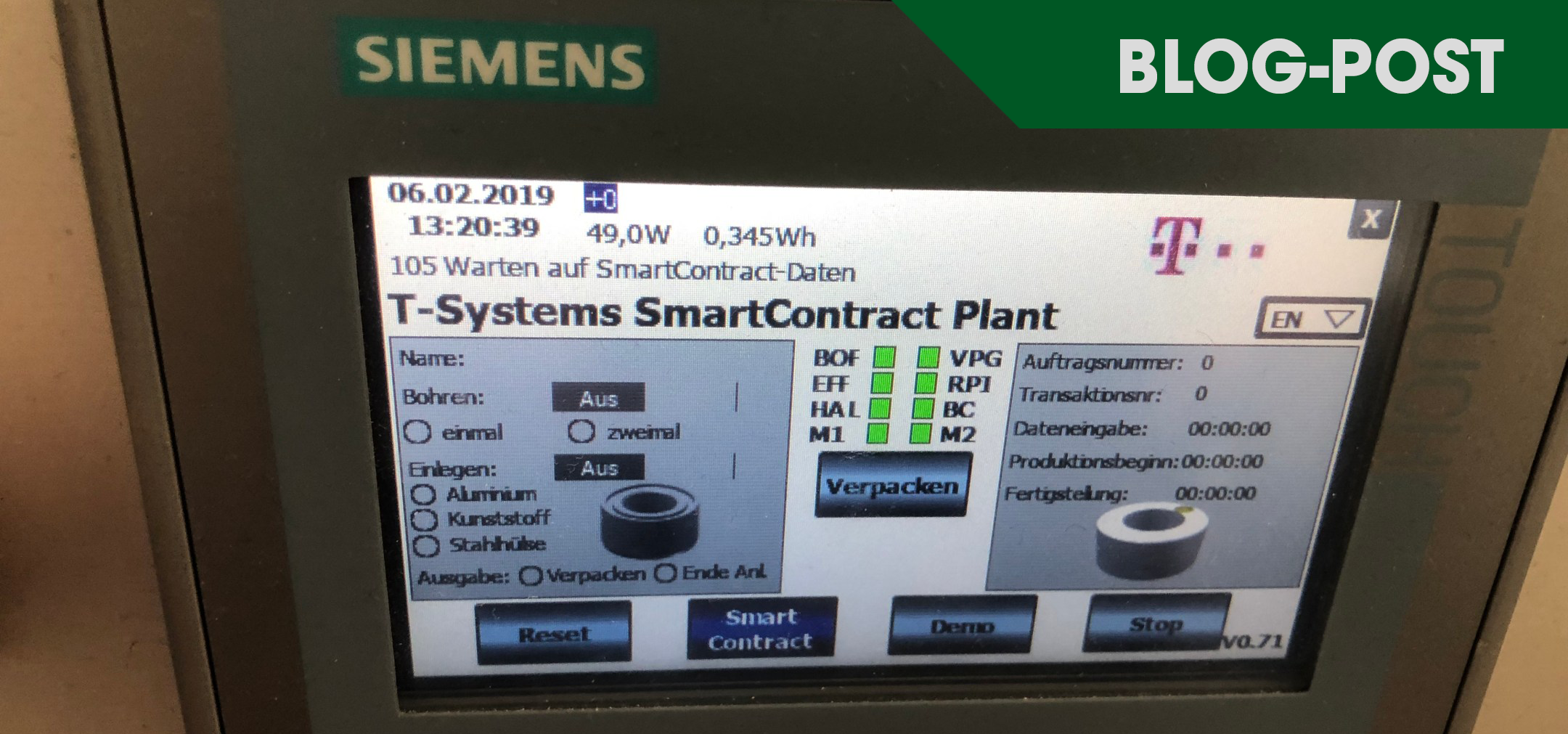

This is the model assembly line they built. It is a mini manufacturing rig that assembles and packages model widgets with embedded RFID tags. There are several assembly options, and the configuration of those options is driven by an Ethereum smart contract.

This working model illustrated — in a way that PowerPoint slides never could, how truly revolutionary the potential is. When we think of disintermediation, we tend to think of brokerages, professional services like accountancy or law, and other facilitators of the information economy. Until I saw this machine, it never occurred to me that manufacturing itself could be disintermediated. Startups and medium enterprises would be able to share expensive and specialized equipment they could otherwise never afford. Smaller medical facilities could do likewise with the most modern diagnostic and imaging tools. Entire factories could tool themselves to meet the needs of separate, small-batch units of demand in real time.

I will need to think about this some more, do some research, and validate ideas with people who have a lot more experience in this area than I do. But the possibility for change here is vast, and my intuition says its full potential won’t be realized until someone can articulate a business and process model that could never have existed without this breakthrough.

That someone is may be the Digital Trust team at T-Systems. They certainly have a head start, and this is only one of several really interesting ideas they have cooking. This team is looking way beyond the standard payment, token, or supply chain solutions that everyone else is building. I am really excited about working with them on this.

0 Comments